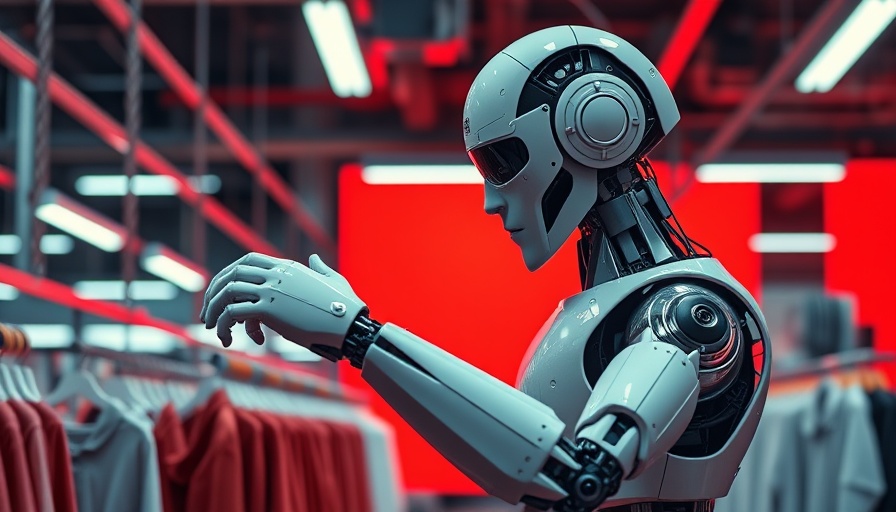

2025: The Dawn of the Humanoid Robot Worker

As we step into 2025, the landscape of manufacturing is on the verge of a revolutionary shift with the introduction of humanoid robots into factories. No longer confined to laboratories, these robots are being designed to translate advanced technologies into practical applications on production floors. The upcoming release of Boston Dynamics’ Atlas robot in Hyundai’s factory highlights this pivotal moment as the industry prepares to embrace the potential of humanoid workers.

The Transformer of Manufacturing

Boston Dynamics is set to lead the way with the Atlas robot, an all-electric humanoid figure that has been extensively reengineered from previous models. Unlike its predecessors, Atlas is built for strength and agility, allowing it to perform tasks that oftentimes prove difficult for human laborers. According to Kerri Neelon, a spokesperson for Boston Dynamics, this robot can carry heavy and awkward objects—functions that could ease physical strains on human workers in a factory setting.

A New Market Emerges

The market for humanoid robots is expected to explode exponentially, with projections estimating a value of $38 billion by 2035. This forecast, highlighted in a recent Goldman Sachs report, is more than six times the market value projected just a year prior. Companies like Agility Robotics and Figure are not far behind, already making inroads into warehousing and distribution, thus marking the entry of humanoid robots into commercial environments.

From Assembly Lines to Flexibility

The major advantage of humanoid robots lies in their versatility. Unlike traditional assembly line systems tailored for specific tasks, humanoid robots can adapt to a multitude of roles. Jonathan Hurst, cofounder of Agility Robotics, emphasizes that while specialized machines are optimal for continuous operations, humanoids can significantly enhance productivity in tasks that vary throughout the day. This adaptability could enable companies to maximize their efficiency while minimizing operational costs.

Humanoid Robots: Reflecting Human Needs

Boston Dynamics touts the design of Atlas as one that has been created to fit into a human-centric world. This ethos is key as companies continue to integrate more automation solutions. The premise is that a successful implementation of humanoid robots will bridge the gap between human capabilities and the growing demands of modern manufacturing.

Overcoming Hurdles: The Road Ahead

While excitement surrounds these innovations, challenges remain. Tesla’s Optimus robot, for instance, has generated much anticipation, but demonstrations revealed that many of the showcased robots were being remotely controlled. Such events raise questions about the true level of autonomy we can expect from these machines—an essential trait if humanoid robots are to function effectively and safely alongside their human counterparts.

Ethical Considerations and Future Predictions

As the adoption of humanoid robots rises, ethical considerations will also come into play. The impact on the workforce and potential job displacements will be hot topics among industry leaders, policymakers, and society at large. It is vital for businesses to address these concerns proactively, striking a balance between technological advancement and workforce security.

What This Means for Business Leaders

For CEOs, marketing managers, and business professionals, understanding the emerging trends in humanoid robotics will be crucial. Embracing these advancements could not only enhance operational efficiencies but also lead to significant competitive advantages. As we anticipate this shift, business leaders must contemplate how to effectively integrate humanoid robots within their operations, addressing both the logistical and ethical dimensions of such integration.

Take Action Now

As we look toward the future shaped by humanoid robot workers, it’s time for industry leaders to engage in strategic planning. Consider how the integration of these robots can be approached in a way that benefits all stakeholders involved. Stay informed, invest in research, and ensure that your organization is ready for the changes that will define tomorrow's manufacturing landscape.

Add Row

Add Row  Add

Add

Write A Comment